DEGACRYL® HS develops new sustainable heat sealing solutions for the food packaging industry

BENEFITS AT A GLANCE:

For decades, industry leaders in the food packaging industry rely on DEGACRYL® HS heat seal binders. Especially in the dairy sector smooth peeling properties are required when opening the products. Evonik’s heat sealing grades like DEGACRYL® HS 666 or DEGACRYL® HS 4313 E, a new solution for PVC-free paper/PET lids, are well established and ensure secured sealed packaging throughout the supply chain – from the dairy manufacturers to the consumer’s refrigerator.

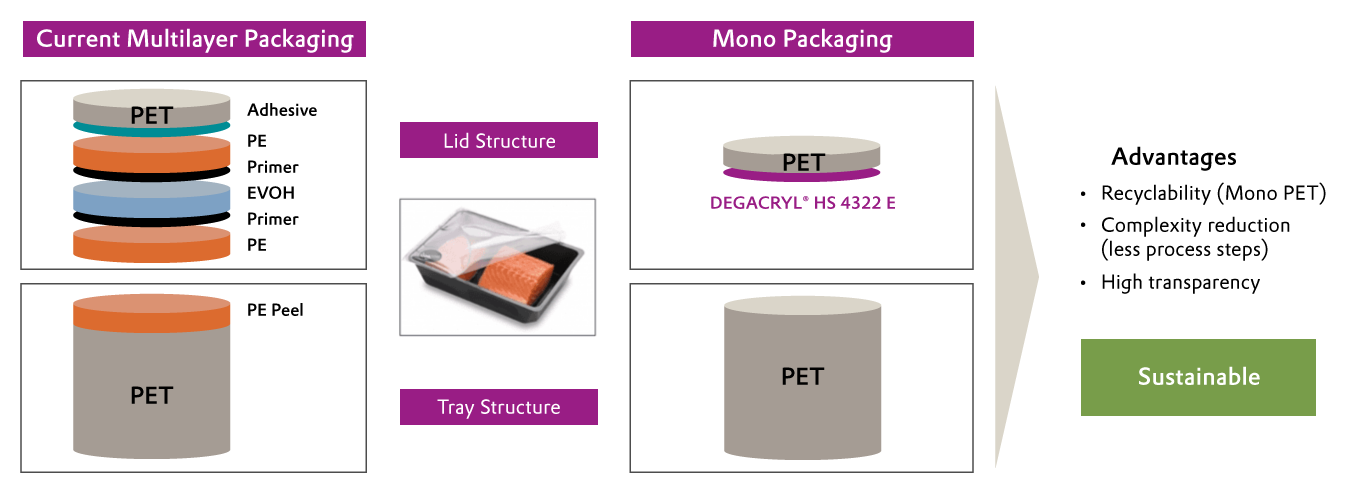

Sustainable solutions are required in every industry and the food industry is no exception. To ensure food packaging can be properly recycled, it needs to consist of a single material. For food packaging that means the lid and tray should be made of the same material. Here, the solvent-based heat seal coating based on DEGACRYL® HS from Evonik offers clear advantages compared to other technologies.

Mono Material Packaging

A circular economy for plastic packaging is only possible by high recycling rates which can be achieved by mono material packaging. DEGACRYL® HS products can be used with a broad range of suitable material combinations, thus facilitates sealing of packaging made from mono material. Additionally, a low coating weight (2 to 6 g/m2) ensures a secured sealing, thus supports the declaration as mono material. Using our universal grades such as DEGACRYL® HS 4313 E or HS 4294 E, it is possible to seal a PET lidding film with a PET container without the need of additional additives. The ease of processing and application furthermore support the recycling of the final packaging.

Figure 1: Schematic comparison of existing multi-layer packaging versus mono material packaging solution using DEGACRYL® HS 4322 E (own data).

Figure 2: Example of mono PET packaging for fresh food with high transparency based on DEGACRYL® HS 4322 E