VERSALINK® products enable coating formulators to improve their processing and sustainable performance

BENEFITS AT A GLANCE:

Sustainability has become increasingly important across the coatings industry in recent years. One of the most important trends is avoiding the use of any toxic materials in coating formulations.

One example is dibutyltin dilaurate (DBTL) and dioctyltin dilaurate (DOTL). While they both have excellent processing properties, such as liquid flow and curing rates, they also come with major drawbacks too, like their mutagenic potential, which makes using them in many applications impossible.

So how can coatings formulators meet such high sustainability demands while still maintaining good processability, excellent flow properties, fast cure rates and high-performance?

The VERSALINK® series offers exactly the properties needed to meet all these requirements.

Due to its primary amine groups, VERSALINK® can react with MDI type isocyanates without the use of any catalyst even at room temperature. In contrast to typical polyurea systems, VERSALINK® provides long pot lifetime, so that even application by hand is possible. In addition, VERSALINK® products are not labelled as carcinogenic, mutagenic, or toxic for reproduction (CMR) products and are completely non-hazardous for the user.

Evonik offers VERSALINK® products with different molecular weights. The physical properties and reactivities will change depending on the chosen grade. Formulators can combine multiple grades to tailor the end properties. If the reactivity is too low the rate of reaction can be improved by adding 0.2-1.0 wt% of the DABCO® BA 100 catalyst, a nontoxic and low emissive acidic compound that can react into the polymer matrix.

To provide a low temperature liquid grade that offers similar flexibility as VERSALINK® P 2000, Evonik has introduced VERSALINK® EP-AT-V 15. This low reactivity grade can be utilized to produce highly flexible coatings without any pre melting.

In addition, Evonik has developed a new biobased VERSALINK® grade which fulfills the demand for components with a low CO2 footprint and made of renewable raw materials. This special grade provides similar material properties as VERSALINK® P 1000 but offers more than 80 wt% renewable carbon.

One example is dibutyltin dilaurate (DBTL) and dioctyltin dilaurate (DOTL). While they both have excellent processing properties, such as liquid flow and curing rates, they also come with major drawbacks too, like their mutagenic potential, which makes using them in many applications impossible.

So how can coatings formulators meet such high sustainability demands while still maintaining good processability, excellent flow properties, fast cure rates and high-performance?

The VERSALINK® series offers exactly the properties needed to meet all these requirements.

Due to its primary amine groups, VERSALINK® can react with MDI type isocyanates without the use of any catalyst even at room temperature. In contrast to typical polyurea systems, VERSALINK® provides long pot lifetime, so that even application by hand is possible. In addition, VERSALINK® products are not labelled as carcinogenic, mutagenic, or toxic for reproduction (CMR) products and are completely non-hazardous for the user.

Evonik offers VERSALINK® products with different molecular weights. The physical properties and reactivities will change depending on the chosen grade. Formulators can combine multiple grades to tailor the end properties. If the reactivity is too low the rate of reaction can be improved by adding 0.2-1.0 wt% of the DABCO® BA 100 catalyst, a nontoxic and low emissive acidic compound that can react into the polymer matrix.

To provide a low temperature liquid grade that offers similar flexibility as VERSALINK® P 2000, Evonik has introduced VERSALINK® EP-AT-V 15. This low reactivity grade can be utilized to produce highly flexible coatings without any pre melting.

In addition, Evonik has developed a new biobased VERSALINK® grade which fulfills the demand for components with a low CO2 footprint and made of renewable raw materials. This special grade provides similar material properties as VERSALINK® P 1000 but offers more than 80 wt% renewable carbon.

| Physical Properties of VERSALINK® Diamines | |||

|---|---|---|---|

| Grades | Viscosity (mPa’s at 25°C) |

Physical State (25°C) | Amine Equivalent Weight (g/eq) |

| VERSALINK® P 250 | solid | solid (mp 60 °C) | 220 - 250 |

| VERSALINK® P 650 | 2,500 | liquid | 335 — 475 |

| VERSALINK® P 1000 | 3,000 | liquid | 575 - 625 |

| VERSALINK® P 2000 | solid | solid* (mp 35°C) | 940-1245 |

Improved material properties with VERSALINK® P Series

VERSALINK® products enhance the chemical and mechanical resistance of coatings. Due to its ester-ether co-structure they combine advantages from both materials. This leads to elastomers with high hydrolytic stability resulting from PTMEG moieties, and higher tear resistance resulting from the ester units.Table 2 depicts the outstanding chemical resistance against water, basic aqueous solutions and chemical solvents like hexane and propylene carbonate, making VERSALINK® products ideal for formulating coatings for chemical and wastewater tanks. Another notable benefit is that the material recovers its initial mechanical properties, even when solvents like hexane have evaporated from the films.

In combination with aliphatic isocyanates, VERSALINK® products enable transparent films, while the tendency to yellow depends on the chosen types. While VERSALINK® P 2000 only has a low yellowing tendency, this will increase slightly when types with lower molecular weight like VERSALINK® P 250 are chosen.

| Chemical Resistance Comparison Immerson with 3 mm thick films |

|||||

|---|---|---|---|---|---|

| Curative/system | DIW 100°C (2h) |

15% NaOH 60 °C (24h) |

Hexane RT (24) |

Prop. carb. RT (24h) |

Me-OH RT (24h) |

| PTMEG + TDI + DMTDA |

A | A | B | A | C |

| PPG+TDI + DMTDA |

A | A | B | A | C |

| Polyester + TDI + DMTDA |

A | F | A | C | B |

| VERSALINK® P 1000 + Liquid MDI |

A | A | B | B | C |

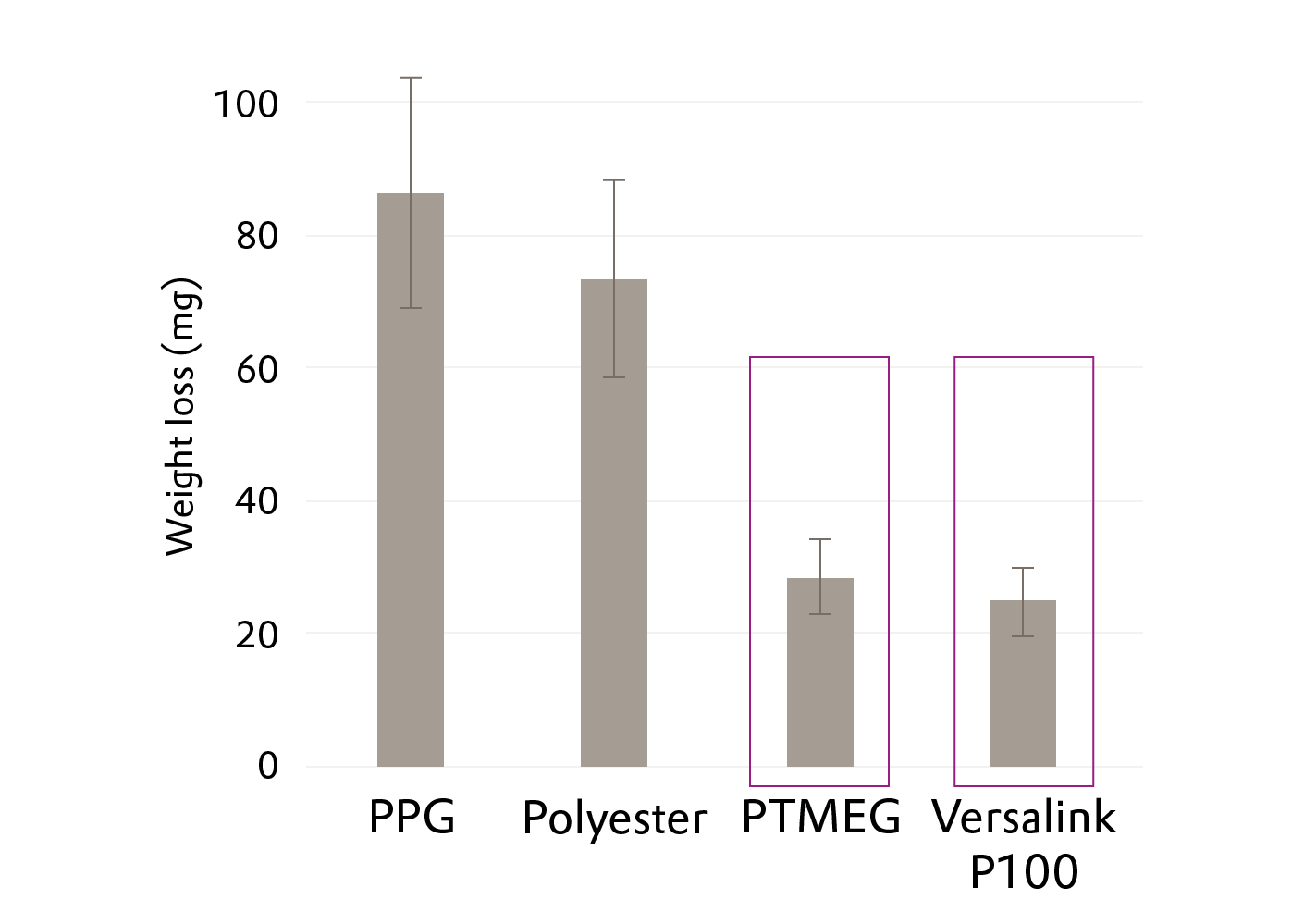

The excellent abrasion resistance is illustrated in Figure 3. VERSALINK® P 1000 sample loses less than half of the mass compared to samples created with Polypropyleneglycols (PPG) or Polyesters.

Taber Abrasion after 5000 cycles with Stone Wheel.