TEGO® Dispers 780 W is a new waterborne dispersant offering customers an all-in-one solution for classical resin containing grinds, resin-reduced and resin-free grinds

BENEFITS AT A GLANCE:

All-in-one solution for water-based pigment grind

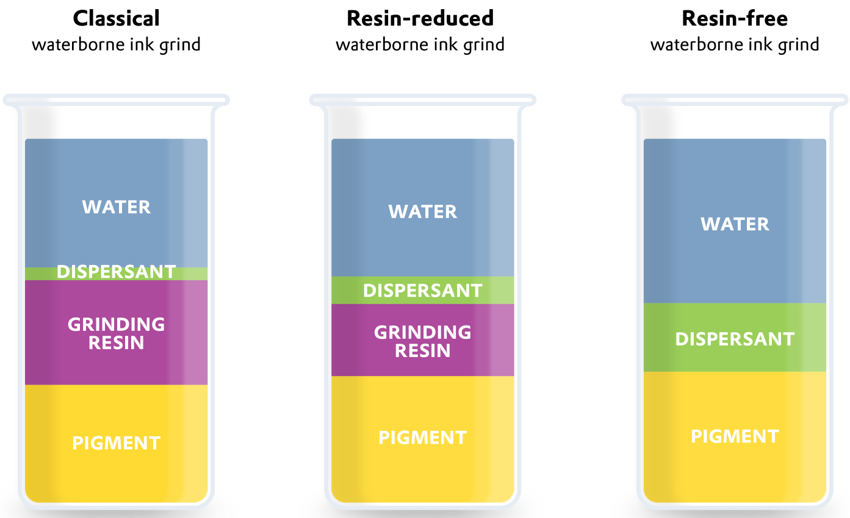

Traditionally, classical resin containing grinds and resin-free grinds tend to have different requirements. Since grinding resins offer certain stabilization effects, the dispersant in resin containing grinds is utilized mostly to boost pigment wetting. In resin-free grinds, however, additional dispersant is required to provide both pigment wetting and long term stabilization. Finding one product that fits the needs of multiple complex systems has been the challenge for many years. TEGO® Dispers 780 W is a new waterborne dispersant offering customers an all-in-one solution for classical resin containing grinds, resin-reduced and resin-free grinds as showed in Figure 1.

Figure 1: Visual comparing classical resin containing grind, resin-reduced grind and resin-free grind

Suitable for a broad range of pigments

TEGO® Dispers 780 W not only fits the need of different resin systems, it also shows great performance in different types of pigments, including but not limited to: Pigment Blue 15:3, 15:4, Pigment Red 122, 57:1, Pigment Yellow 13, 74, Pigment Black 7 and TiO2. High throughput equipment was utilized to screen and test the performance of TEGO® Dispers 780 W. Figure 2 illustrates how the viscosity reduction and stability with this new product in resin-reduced grind is significantly better than internal and external Benchmarks 1 and 2.Outstanding viscosity reduction

Resin-reduced grind

40% PY13

5 % ASOP

Viscosity at 100 1/s

Fresh and after 2 weeks @50°C

Figure 2: TEGO® Dispers 780 W shows outstanding viscosity reduction (purple bar) and stability (grey bar) in a resin-reduced grind with 40% Pigment Yellow 13.

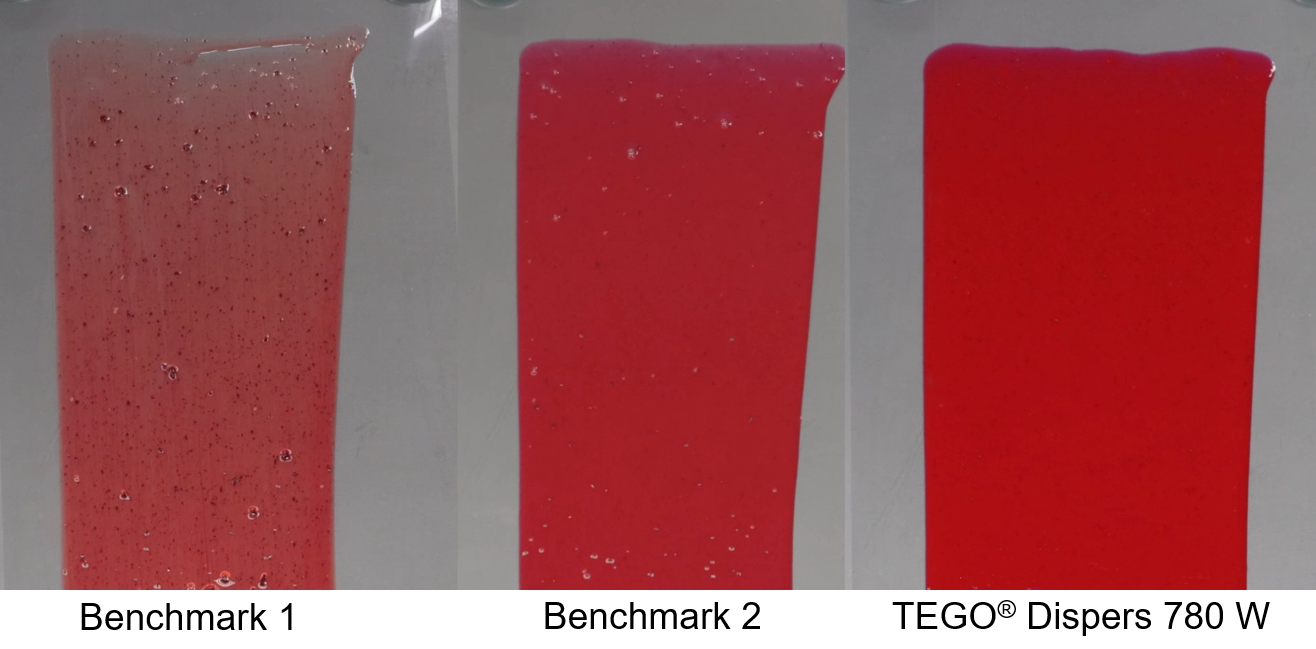

Superior stabilization and shock resistance

One of the major challenges in mixing the grinding stage with the letdown stage is pigment shocking. In other words, creating a pigment dispersion that is stable under elevated temperature is only part of the developing work. The other part is to check the compatibility between the dispersion and a wide variety of different let-down resins to make sure that no pigment flocculation and phase separation could be observed. This effect is best illustrated in Figure 3 where Benchmark 1 and 2 show pigment shocking and weak color development. The new product really stands out compared to the competition in the market, making it an excellent choice for universal pigment types of resin systems.

Figure 3: Pigment shocking test: 0.5 g of the pigment dispersion was added into 50 g of let-down resin, the mixture was then stirred with a spatula for 30 seconds. Finally, the mixture was poured onto PET film. The dispersion with TEGO® Dispers 780 W demonstrated no pigment shocking and offered better color strength comparing to Benchmark 1 and 2.

Safe and sustainable solution as dispersant

With the growing focus on safety in end-use applications, finding a solution that not only fits the technical needs of excellent viscosity reduction and outstanding color strength development but also offer a sustainable solution is becoming even more critical. TEGO® Dispers 780 W is a low viscosity, non-hazardous and solvent-free product with approximately 35% solids in water. It is very easy to handle and complies with numerous food contact regulations such as Swiss Ordinance A list, FDA 21 CFR 175.300, FDA 21 CFR 176.170, FDA 21 CFR 176.180. More detailed information can be found by visiting the links shown below.