Beyond Biobased - Creating possibilities for a sustainable world with methacrylates

BENEFITS AT A GLANCE:

VISIOMER® stands for uncompromising products with reduced carbon footprints, lower global warming potential, and improved safety profiles. With building blocks from our VISIOMER® Specialty Methacrylates ToolBox you can render your applications more sustainable. Whether you use low hazardous monomers or building blocks for ambient temperature curing to improve the handprint of your products or you opt for biobased methacrylates to reduce the product carbon footprint, let VISIOMER® Specialty Methacrylates be your choice!

The VISIOMER® Terra product family

For more than a decade, Evonik has produced monomers made from up to 85 % biobased raw materials under the growing VISIOMER® Terra brand. This is part of our long-term strategy to protect the environment and mitigate climate change without compromising performance. VISIOMER® Terra biobased monomers must not only meet the highest performance requirements, but they are also characterized by a low hazard potential and are designed for environmental friendliness.

The bio-content of VISIOMER® Terra methacrylate monomers is certified by DIN CERTCO and will include the label “Certified Biobased Product.” DIN CERTCO certifies products using the C14 radiocarbon method and ASTM D 6866:2021 protocol. Competitive products often merely calculate bio-content and cannot be independently verified.

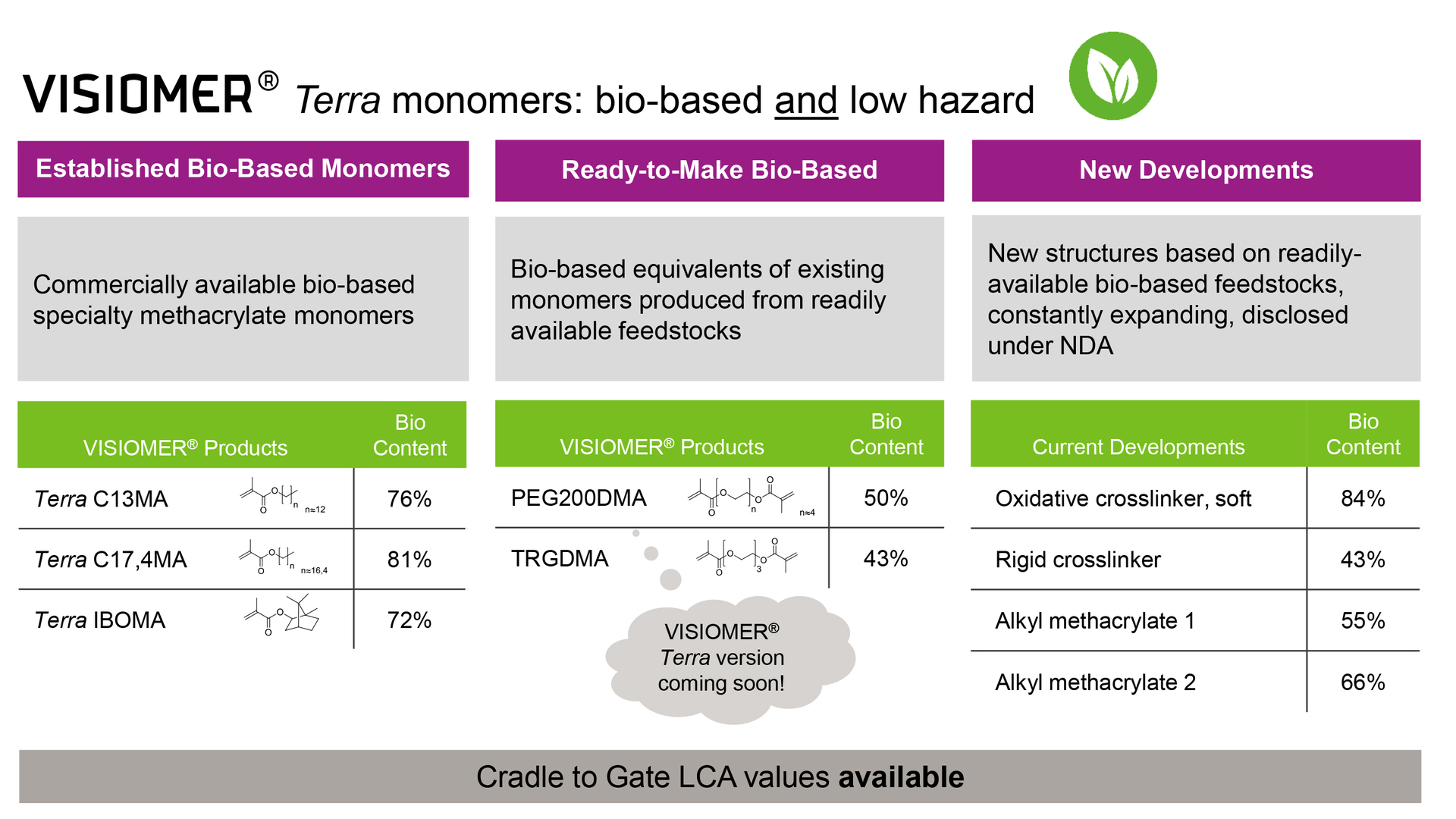

Our motivation is both to use bio-renewable raw materials and to offer added value for the end applications. It is our ambition to further expand the portfolio with more VISIOMER® Terra products. This can be done by either using biobased feedstock instead of fossil feedstock for the existing monomers in our portfolio or by developing new structures based on readily available biobased raw materials. An overview is given in the following Table 1.

Table 1. Overview of existing and future VISIOMER® Terra portfolio.

Our new generation of VISIOMER® Terra Methacrylates – oxidative crosslinker, rigid crosslinker, and alkyl methacrylates based on sustainable resources

The VISIOMER® Terra oxidatively crosslinking methacrylate enables post-crosslinking at ambient temperatures that leads to improved properties of the final coating at low minimum film formation temperatures. Crosslinking after film formation improves the mechanical and chemical properties, additionally curing at ambient temperature saves energy and solvent. The VISIOMER® Terra oxidatively crosslinking methacrylate even allows for the reduction or substitution of co-solvents in water-borne coatings.

Acrylic resins containing oxidatively crosslinkable VISIOMER® Terra methacrylate show an excellent compatibility with alkyd resins, i.e., a combination of both acrylic and alkyd resins unites the advantages of both systems, such as enhanced weathering resistance and improvement of open time in water-based systems.

The VISIOMER® Terra rigid crosslinker may be used as a co-monomer in the core of core-shell systems. The crosslinking efficiency and tensile strength is effectively increased compared to a conventional, fossil-based crosslinker, such as EGDMA. Another key benefit of the VISIOMER® Terra rigid crosslinker is its low polymerization shrinkage of just 8%. This along with the excellent mechanical properties makes it indispensable for adhesives, composites, and various other applications.

Sustainability beyond the biobased aspect

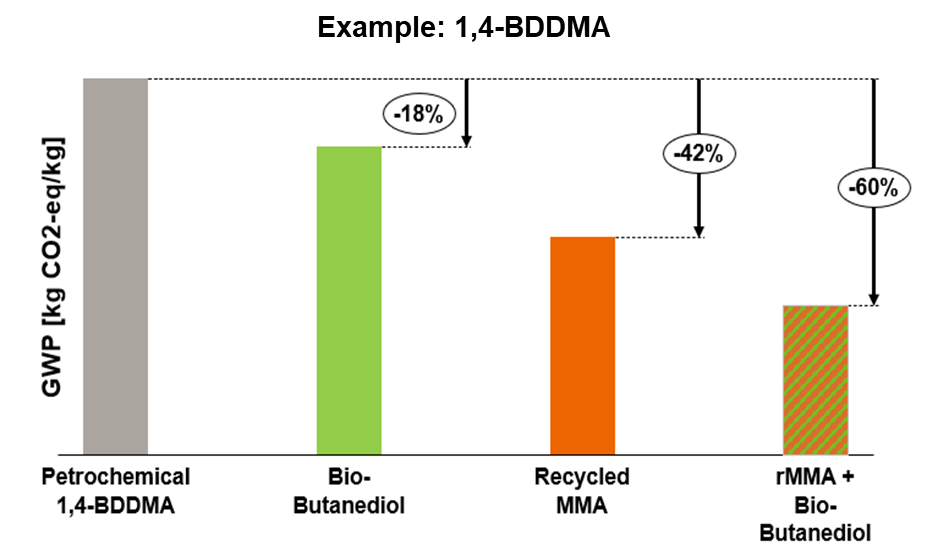

Using biobased raw materials does not necessarily imply lower carbon footprints of the biobased methacrylates as compared to their fossil-based counterparts. Additional aspects, such as raw material origin, distance of transportation, production set-up, energy sources etc. also play an important role. It was therefore our ambition to calculate the global warming potentials (GWP) for our VISIOMER® Terra products to guarantee to our customers a reduced carbon footprint compared to their petrochemical analogues.

Table 2. Global warming potential of 1,4-BDDMA produced from recycled MMA and bio butanediol as compared to petrochemical 1,4-BDDMA.

Sustainable VISIOMER® Terra methacrylates cannot only improve the performance of acrylic coatings but also contribute to a significant reduction of their carbon footprint. On top of these benefits, ambient-temperature curing, or low-VOC properties further add to the sustainability of coatings.