Adhesion promoter, anticorrosion & flame retardant agent for coatings

BENEFITS AT A GLANCE:

VISIOMER® HEMA-P: AN OVERVIEW

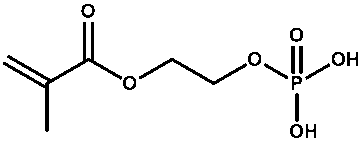

2-Hydroxyethyl-Methacrylate-Phosphate (HEMA-P) is a well-known adhesion promoter in applications like adhesives and coating resins. Evonik offers VISIOMER® HEMA-P 70 M and VISIOMER® HEMA-P 100. A comparison of the two products can be found in Table 1.

Figure 1: Structure of the active ingredient in VISIOMER® HEMA-P.

| VISIOMER® HEMA-P 70M | VISIOMER® HEMA-P 100 | |

|---|---|---|

| Supply | in 30% MMA | pure |

| Viscosity | 40-75 mPa*s | 3000 - 7000 mPa*s |

| P-content | 10.6% | 15% |

| Application Areas |

- Emulsion Polymerization - Bulk Polymerization - Reactive Resins |

- All application areas where MMA is critical due to VOC, odor, flammability or performance |

Table 1: Comparison of VISIOMER® HEMA-P 70M and VISIOMER® HEMA-P 100.

ADHESION PROMOTION

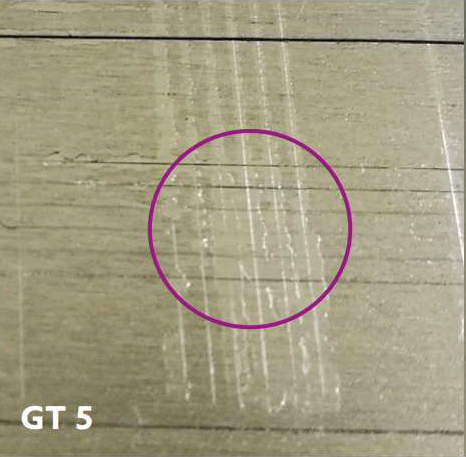

VISIOMER® HEMA-P products can be used as functional co-monomers for adhesives and coatings. They enable superior adhesion to polar surfaces like minerals, glass, and metals.In emulsion coatings, the addition of the adhesion promoter VISIOMER® HEMA-P 70M boosts the adhesion of emulsion-based films on metal substrates from GT5 to GT1, as shown in Figure 2.

Without adhesion promoter

With VISIOMER® HEMA-P 70M

Figure 2: Cross-cut test for emulsion coatings on metal substrates with 7 wt% and without VISIOMER® HEMA-P 70M.

VISIOMER® HEMA-P is a specialty methacrylate, which improves adhesion dramatically even at low concentrations. It merges high polarity with adequate flexibility, making it an added value for new resin formulations.

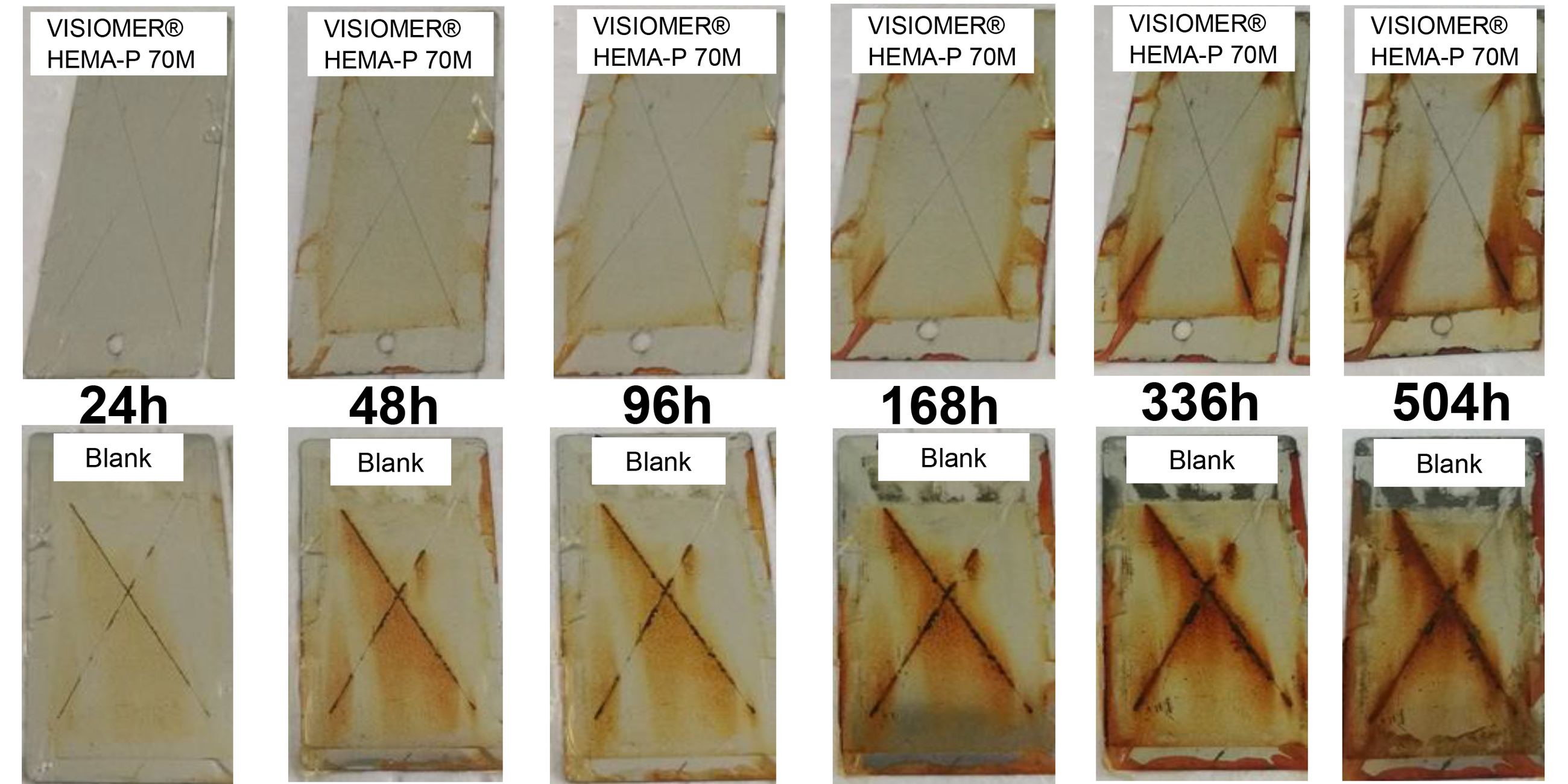

CORROSION PROTECTION

Corrosion protection has always been an important requirement for coatings. The trend towards waterborne systems makes anti–corrosion properties a challenge.Studies on acrylic emulsions with 7 wt% of VISIOMER® HEMA-P 70M demonstrate enhanced corrosion resistance compared to resins without any anti-corrosion agent (Figure 3). Panels coated with VISIOMER® HEMA-P 70M containing emulsion polymers withstood corrosion up to 168 hours in a saltwater immersion test.

FIGURE 3: Salt-spray test on galvanized steel substrate for emulsion coating with 7 wt% and without VISIOMER® HEMA-P 70M.

FLAME-RETARDANCY

New regulations drive industry interest towards alternatives for conventional halogen-based flame-retardants, alternatives that are non-migrating and less hazardous.

VISIOMER® HEMA-P is a polymerizable flame-retardant comprising a smart combination of a phosphoric acid and methacrylate moiety, and the phosphate function is responsible for the flame-retardant properties of the product. The methacrylate group readily polymerizes and leads to a non-migrating agent. Depending on flame-retardant performance targets, the VISIOMER® HEMA-P products can replace flame- retardant additives partly or completely.

A single-flame source test was conducted on acrylic polymer emulsions containing 14 wt% VISIOMER® HEMA-P 70M (Movie 1). It confirms the flame-retardant properties of VISIOMER® HEMA-P 70M containing emulsions.